Injection production is a highly precise manufacturing process that allows the creation of complex, high-quality parts used in industries such as automotive, consumer electronics, and medical devices. The injection molding process involves injecting molten material into a pre-made mold cavity, where it cools and solidifies into a desired shape. This process is widely used for the mass production of plastic parts, injection parts, and many other products that require precision and efficiency.

In this article, we will explore how injection molding works, the steps involved in manufacturing an injection part, and what materials and equipment are used in the injection molding processing. We will also provide insights into the role of injection mold manufacturers and injection molding machines in creating high-quality plastic injection molds and injection molding parts. Additionally, we will explore the latest trends in product injection molding and how businesses are optimizing their manufacturing processes.

Introduction to Injection Molding

Injection molding is a popular manufacturing method used to produce parts in large quantities. It involves injecting molten material—typically plastic or metal—into a mold under high pressure. The material is then allowed to cool and solidify inside the mold cavity, taking the shape of the mold. This process is used to create both simple and highly complex parts, ranging from small, intricate plastic injection parts to larger injection molding parts used in industrial applications.

The benefits of injection molding include high production efficiency, the ability to create intricate designs, and minimal material waste. Additionally, it allows for the production of large quantities of plastic parts with uniform quality, which is why it is favored in industries requiring mass production.

The Basics of Injection Production

Before delving into the process of injection molding, it is important to understand the key components and how they work together to create high-quality molded parts.

Injection Molding Machine

The injection molding machine is the heart of the injection production process. It is responsible for melting the material and injecting it into the mold. There are three main components of an injection molding machine:

The Hopper: The hopper holds the raw material, which can be in the form of pellets, granules, or powders.

The Barrel: The barrel is heated to melt the material. The material is then forced into the mold cavity under high pressure using a screw or plunger.

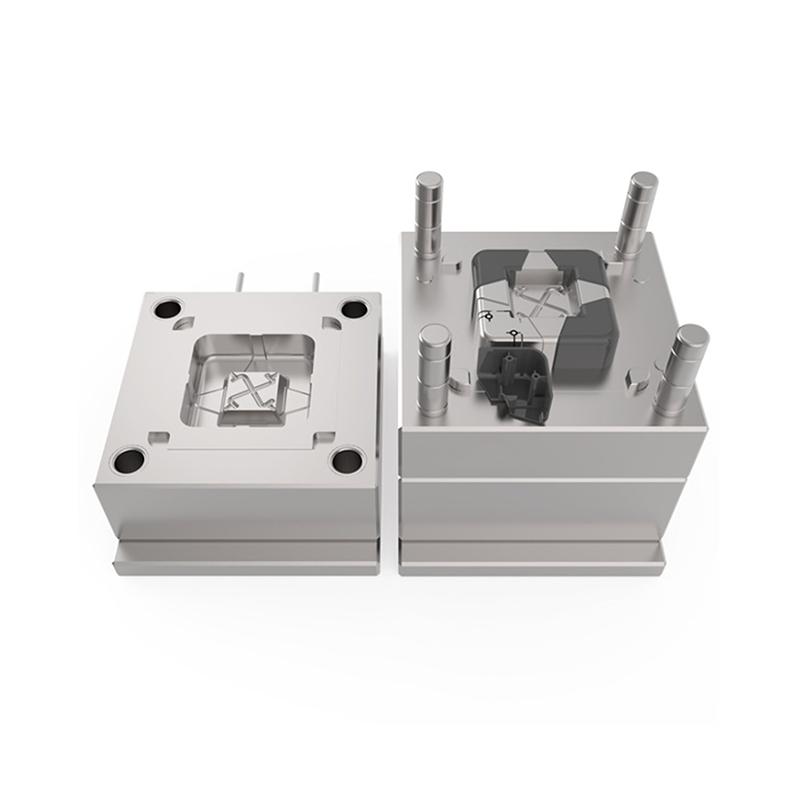

The Mold: The mold is a hollow container that gives shape to the material. The mold is typically made of high-quality steel or aluminum and has a cavity that matches the desired part shape.

The machine’s cycle begins by heating the raw material until it becomes molten. Once molten, the material is injected into the mold, where it fills the cavity and solidifies as it cools.

Injection Mold Manufacturer

An injection mold manufacturer plays a critical role in designing and creating the molds that are used in the injection molding process. The manufacturer uses advanced technologies and materials to produce molds that are precise, durable, and capable of withstanding the high pressures and temperatures involved in the injection molding processing.

The mold is typically made from materials like steel or aluminum. Steel is often used for molds that will be subjected to high-stress conditions or large production runs, while aluminum is preferred for molds that require faster cooling times or lower-volume production. The mold must also be designed with features like cooling channels to ensure that the material cools evenly.

Product Injection Molding Process

The product injection molding process can be broken down into several key steps. Each step is critical to ensuring that the final product meets the required specifications for quality, durability, and performance.

Step 1: Material Selection

The first step in injection molding is selecting the right material. This can be plastic (such as ABS, polypropylene, or polycarbonate), metal, or other specialized materials. The material must be selected based on the desired properties of the final part, including strength, flexibility, and heat resistance.

Step 2: Mold Design

The next step is designing the mold. The mold design is a critical factor in determining the success of the injection molding service. A well-designed mold ensures that the material is injected into the cavity properly and that the mold is easy to eject. The mold also needs to account for features such as cooling channels, ejection mechanisms, and venting to prevent defects in the molded part.

Step 3: Injection

Once the mold is ready, the injection molding machine heats the material and injects it into the mold cavity. The material is injected at high pressure to fill every corner of the mold. This process ensures that even the most intricate designs are replicated with precision.

Step 4: Cooling

After injection, the molten material begins to cool and solidify. Cooling time depends on factors such as the material used, the mold design, and the thickness of the part. The cooling process must be carefully controlled to ensure uniform cooling and to avoid warping or distortion of the part.

Step 5: Ejection

Once the part has cooled and solidified, it is ejected from the mold using an ejection system. This system typically consists of ejector pins that push the part out of the mold. The part is then inspected for defects, and any excess material is trimmed away.

Step 6: Post-Processing

Some parts may require post-processing to achieve the desired finish or functionality. This can include processes such as painting, assembly, or adding additional components. In some cases, the molded parts are subjected to secondary operations like CNC machining to refine their dimensions.

Injection Molding Processing and Equipment

The injection molding processing involves a range of sophisticated equipment and machinery designed to ensure the efficient production of high-quality parts. The plastic injection machine plays a vital role in this process, as it is responsible for melting and injecting the material into the mold.

Modern injection molding machines are equipped with advanced control systems that regulate parameters such as injection speed, pressure, and temperature. These controls ensure that the injection molding parts are produced consistently, meeting the required specifications for each production run.

Injection Molding Service Providers

Choosing an experienced injection molding service provider is crucial for ensuring that your project is completed on time and to the highest quality standards. These providers offer a range of services, including mold design, material selection, production, and post-processing. Whether you're creating plastic parts, injection parts, or complex components, a reliable injection molding service provider can help streamline the entire manufacturing process.

At HAGO, we specialize in providing comprehensive injection molding services that meet the needs of our clients across various industries. From plastic injection molds to advanced injection molding machines, our team is dedicated to delivering high-quality, cost-effective solutions.

FAQs

Q1: What is injection molding?

A1: Injection molding is a manufacturing process in which molten material is injected into a mold cavity under high pressure. The material then cools and solidifies, taking the shape of the mold.

Q2: What materials are used in injection molding?

A2: Common materials used in injection molding include plastics such as ABS, polypropylene, and polycarbonate. Other materials like metals and specialized polymers can also be used depending on the application.

Q3: What is an injection mold manufacturer?

A3: An injection mold manufacturer is a company that designs and produces molds used in the injection molding process. These manufacturers use advanced materials and technologies to create molds that ensure the production of high-quality parts.

Q4: What is the role of an injection molding machine?

A4: The injection molding machine is responsible for melting the material and injecting it into the mold cavity. It controls the temperature, pressure, and injection speed to ensure the proper formation of the molded part.

Q5: How do I choose the right injection molding service?

A5: When selecting an injection molding service, consider factors such as the company’s experience, expertise in your industry, the range of services offered, and their ability to meet your production requirements.

Q6: How long does the injection molding process take?

A6: The injection molding process can take anywhere from a few seconds to several minutes, depending on factors such as the complexity of the part, material type, mold design, and cooling time.

Q7: What is the difference between injection molding and other manufacturing processes?

A7: Unlike other manufacturing processes such as casting or machining, injection molding allows for the high-volume production of complex, precise parts with minimal waste and fast cycle times. It is especially suited for plastic parts and injection parts.

Injection production is a critical process in modern manufacturing, enabling the mass production of high-quality plastic parts, injection parts, and other components. From selecting the right material to designing and creating molds, the process of injection molding involves a combination of sophisticated equipment and skilled professionals. Whether you’re working with plastic injection molds, injection molding machines, or other specialized equipment, it’s important to partner with an experienced injection mold manufacturer to ensure your production is efficient, precise, and cost-effective.

By understanding the intricacies of injection molding processing and the equipment involved, manufacturers can optimize their operations to produce the best possible results for their clients. Whether you’re producing plastic injection molding parts or creating complex components for the automotive or medical industries, the right approach to injection production can lead to significant improvements in both quality and efficiency.